Although making the leap into digital inkjet product decoration can be a daunting challenge, there are many reasons for doing so. Despite having a higher upfront capital cost, on average, as compared to traditional analog methods of product decoration, industrial inkjet printers offer many advantages over other methods. Below are six of the top reasons for converting to digital.

1. Industrial Inkjet Printers Offer “Contact-less” Printing For Delicate Substrates

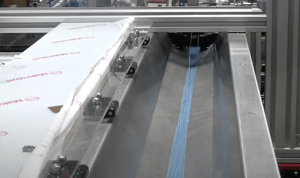

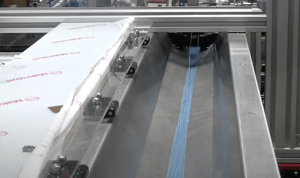

Analog methods of product-decoration such as pad printing press the ink onto the part. Delicate parts such as light bulbs or Christmas ornaments do not lend themselves to such methods. With digital inkjet printers, there is no actual contact with the part, as the ink is jetted from as much as 10 mm away. In addition, all of our industrial inkjet printers use UV-curable inks. After receiving the ink, the part passes under an LED lamp and is instantly cured by UV light, without heat.

2. Industrial Inkjet Printers Enable Quick Changeovers

To set up a pad print job, you must first create a cliché with the image to be transferred to the part. Additionally, pad print machines use spot colors, so the ink must be mixed and loaded into the ink cup.

With industrial inkjet machines, there is no cliché, as ink is jetted direct-to-object. In most cases, there is no ink to change out as industrial inkjet machinery uses the process colors of cyan, magenta, yellow, and black.

3. Industrial inkjet Printers Enable Variable Data

Because the image is digital and there are no clichés, industrial inkjet printers are ideal for printing sequential serial numbers on otherwise-static artwork. So, for example, you could print a 10,000-unit run with identical branding and product information but with each one having a unique serial number.

This leads to perhaps the single-biggest reason to convert to industrial inkjet printers for product decoration…

4. Industrial Inkjet Printers Make Short Runs Economical

Any time a machine is not running, it is costing its owner money. With analog methods of product decoration, the way to maximize overall equipment effectiveness is through minimizing changeovers and make-ready work generally, and maximizing run lengths.

With industrial inkjet printers, once the artfile has been stored in the printer, it can be recalled with a touch of a button, and there are no clichés, inks, or pads to change out. One-off production becomes a possibility. And with no ink or clichés to change out…

5. There Is Less Waste With Industrial Inkjet Printers

With pad print machinery, any unused ink in the ink cup is simply wasted. With industrial inkjet printers, the ink is constantly recirculated, and most parts can be decorated in high-resolution CMYK for mere pennies, depending on the size and complexity of the art to be printed.

6. Industrial inkjet Printers Facilitate Leaner Inventories

When printing direct-to-object with an industrial inkjet printer, there are no labels to keep in inventory. This saves precious floor-space in a factory. In addition, because short runs can be economical when using industrial inkjet machinery, many parts can be left in an unfinished state and decorated on-demand in just-in-time fashion. This can reduce the need to warehouse finished goods, again saving a company money.

Click for free download.

There are many factors to consider when contemplating converting from analog to digital methods of product-decoration. (You can download our White Paper on the subject here: Investing In Digital Printing: 5 Factors To Evaluate) Industrial inkjet printers are not the solution for every print job or for every company. But despite a typically higher initial CapEx than with analog methods of product-decoration, inkjet printers can start saving money in myriad ways. We hope you enjoyed the six we’ve listed here.

Want to find out more about industrial inkjet printers? Drop us a line!

After a terrible year in which so far over 260,000 Americans have succumbed to the novel coronavirus, and with millions more deaths worldwide, it appears as though there is light at the end of the tunnel. No fewer than three different vaccines are either in final stages of testing or are in the initial phases of being rolled out to patients.

After a terrible year in which so far over 260,000 Americans have succumbed to the novel coronavirus, and with millions more deaths worldwide, it appears as though there is light at the end of the tunnel. No fewer than three different vaccines are either in final stages of testing or are in the initial phases of being rolled out to patients.

It is estimated that “herd immunity” occurs when a minimum of 70 percent of the population is vaccinated, which will require two doses. But just how do you quickly vaccinate 320 million Americans—twice each—in a short period of time? Not only do vaccines take time to culture (you can’t cook a Three-Minute Egg in one minute simply by turning up the heat), but so too do all of the ancillary products take time to manufacture, products such as the syringes with which to administer the vaccine.

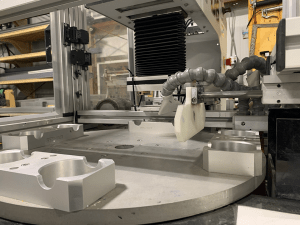

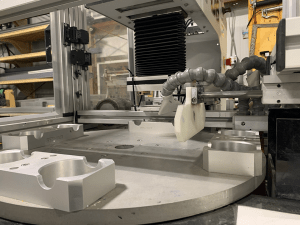

Six hundred and forty million doses means 640 million syringes. How do you scale up and manufacture nearly three-quarters of a billion syringes as quickly as possible? In a word, automation. As with so many manufacturing processes, the bottleneck activity in part-marking is usually the ancillary activities adjacent to the actual process of marking the part, with part loading and unloading being the frequent culprits. For this reason, we have designed the XRV Rotary Syringe Printer for high-speed syringe marking.

With the XRV, the operator loads bulk syringes into a waterfall feeder that cascades into a vibratory bowl feeder. As the parts revolve around the bowl feeder, the syringes fall into a track and become aggregated in proper alignment for marking. The track then loads a rotating table, which moves parts past a rotating drum that houses nine pads, each of which has picked up the image from the rotating cliché, in a manner similar to how offset presses transfer ink from one roller to another. The rotating table moves the freshly-printed parts past a Hot Wind device to quickly cure the ink. Once the part has cured, it is automatically offloaded for secondary activities such as filling, assembly, and packaging.

With fully-automated load and unload and continuous ink-loading capabilities, the XRV rotary syringe printer is ideal for long production runs—the kind of runs necessary to produce billions of doses of a vaccine. If you are looking for ways to speed up your throughput or to dramatically scale up production, give us a call. We manufacture product-marking machinery with custom automation for companies in every industry. Let us help you Change The Way YOU PRINT.

New servo motor replaces step motor for increased repeatability and reliability.

Engineered Printing Solutions is pleased to announce a new version of its celebrated BottleJet Cylindrical Inkjet Printer—the BottleJet 2.1. Highlights include an improved lead screw motion motor, which is now servo-electric instead of a “step” motor for increased repeatability and reliability. Other improvements include an improved bottle fixture, with additional guide rollers that can be installed and removed easily thanks to a quick-release latch. We’ve also added a second mandrel with a shorter stem to accommodate larger bottles.

Engineered Printing Solutions is pleased to announce a new version of its celebrated BottleJet Cylindrical Inkjet Printer—the BottleJet 2.1. Highlights include an improved lead screw motion motor, which is now servo-electric instead of a “step” motor for increased repeatability and reliability. Other improvements include an improved bottle fixture, with additional guide rollers that can be installed and removed easily thanks to a quick-release latch. We’ve also added a second mandrel with a shorter stem to accommodate larger bottles.

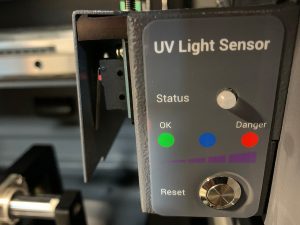

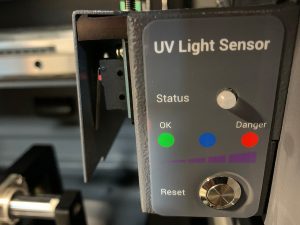

The UV sensor will prevent accidental curing of print heads.

Perhaps the single-biggest change over the previous model is the addition of a UV light sensor to prevent accidental damage to the print heads. If the sensor detects the presence of UV light, the machine cancels the print job and returns to its home position. In addition, there is a new lamp curtain window, which allows the operator to close off unused sections of the lamp that are not required for the curing process. In previous designs you had to remove the second lamp when not in use and tape over any sections that were not being used in the remaining lamp. A new angle-adjustment knob allows speedy adjustments of the curing lamp, where previously it was necessary to loosen a bolt to make adjustments. This time-saving feature will be much-appreciated by operators. Finally, the curing lamp can now be adjusted to have a negative angle, which means that the BottleJet can now print cylindrical objects with the print heads moving from the top of the part to the bottom without the need for reverse-tooling.

The BottleJet 2.1 has other upgrades as well. A new red laser guide on the head carriage enables the operator to easily set the print origin on the part. An improved method for stirring white inks even when the machine is off reduces startup time. Even the firmware has been upgraded to power the new features of the BottleJet 2.1.

Want to find out more about the new BottleJet 2.1 cylindrical inkjet printer? Drop us a line!

The BottleJet 2.1 can produce photo-quality images in under a minute.

In pad printing, seconds matter.

Pad printers are an excellent solution to product-marking and -decoration when runs are long, the artwork is fairly simple, and part topography precludes an inkjet solution. But as with any form of “contact” printing, there are theoretical limits to throughput speed. The pad can only move so fast, or the ink needs a minimum time period to cure before downstream activities can take place.

Doubling the number of pads, plates, fixtures, and parts doubles throughput, but duplication also adds considerably to the cost of the machine. Prospective customers also frequently bring up the topic of a rotary table to move parts past the pads and ink cups, but this only speeds up throughput if there are preliminary steps such as pretreatment for adhesion required for the printing process, as regardless of how many stations there are on a rotary table, the operator still only has two hands with which to load the machine. Another problem with trying to increase throughput through the use of a rotary table is the actual movement of the table itself; the operator can only load parts onto the table when it is stationary.

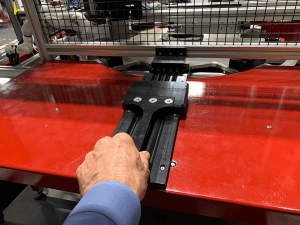

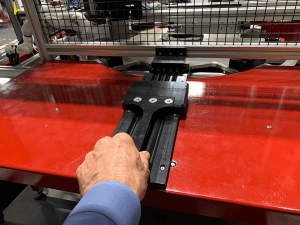

Fig. 1: A simple rake with pneumatic control for off-loading parts can increase throughput by eliminating one human touch.

Sometimes simple additions to standard operations can add significant throughput gains with very little added cost. When trying to increase throughput, a good place to start is in minimizing the number of “touches” a machine operator must make on a part. Either loading or off-loading can be automated. One solution for off-loading parts is a simple rake, driven by pressurized air, to pull parts off of the fixture. (See figure 1.) This frees the operator to focus solely on loading parts into the machine.

Fig. 2: EPS designed this loading mechanism to enable the operator to load parts even while the table is rotating.

EPS has designed a loading mechanism that “pre-loads” parts into position, and then vacuum sucks the parts onto the fixture once the table has come into position and is at a standstill. This automated load can occur much faster than if a human operator had to do it. (see figure 2.)

These are just a few examples of innovative, one-off solutions we have found for our customers. Sometimes, seconds can be gained just by having one of our Sales Engineers visit your facility and discuss your operation. Our experience in manufacturing processes in a wide variety of industry verticals—Automotive, Medical Device, Health & Safety—has taught us many operational strategies that may offer ways to shave precious seconds off your production process. Customers trust us to find a solution to their part-marking problem because they know that we understand that seconds matter; if you can go from a four-second print cycle to a three-second print cycle, over the course of a shift, a day, or a year, those seconds add up to real cost-savings for our customers.

Automated Parts-Handling Can Shave Seconds Off of a Production Process

- Some work environments can benefit by trimming seconds out of their processes.

- Sometimes simple additions to standard operations can add significant throughput gains with very little added cost.

- Sometimes seconds can be gained just by having a Sales Engineer come in to discuss your operation. Our experience in manufacturing facilities across industry verticals exposes us to many operational strategies that may offer ways to save you time and money.

Want to find out more about custom automation solutions for your part-marking job? Drop us a line!

Enhance the safety of your employees while promoting brand awareness. Putting your logo on your company’s hard hats isn’t just good marketing; it could also make your employees safer. And Engineered Printing Solutions currently has a unique opportunity for a turnkey hard hat pad printing system.

Enhance the safety of your employees while promoting brand awareness. Putting your logo on your company’s hard hats isn’t just good marketing; it could also make your employees safer. And Engineered Printing Solutions currently has a unique opportunity for a turnkey hard hat pad printing system.

The coronavirus pandemic has wreaked havoc on long-term plans for many businesses. Unforeseen shifts in supply and demand have upset traditional industries (who knew that the moribund retail grocery industry would have such a banner year?) and made instant superstars out of startups (hello Zoom). Other companies have rejiggered capital investment plans, some speeding up projects to take advantage of historically cheap money while others are cancelling projects that no longer make sound business sense.

In May of this year, one company that falls into the latter category took delivery of a hard hat pad printing system designed and built by Engineered Printing Solutions. Due to the rapidly-changing business climate in the age of Covid-19, the project for which the system was purchased was cancelled before our customer even had time to uncrate the machine, and EPS agreed to find a buyer for this never-used equipment. This represents an incredible opportunity for someone looking for a turnkey hard hat printing solution, as the system is crated and ready for delivery, with zero lead time, as all of the development of the system such as finding the right pretreatment method and part transport system has already occurred.

At the heart of the machine is a KP08 3 Color Extended Neck pad printer, with three 110mm circular ceramic-ring style sealed ink cups and three pads. Integrated twin plasma pretreatment nozzles ensure perfect adhesion. A heavy-duty five-station linear servo shuttle transports the part for printing, and a servo-controlled rotational fixture rotates the part for printing on all sides. An automatic programmable pad cleaner cleans the pad at operator-specified intervals, or at preprogrammed setpoints, for perfect image quality every time.

With three pads, the machine can be programmed for a variety of print modes:

- 3 single images at three discreet locations, with up to three colors each

- One single color image at one location

- One 2-color image at one location and a single-color image at another location

- Two single-color images at two locations

- One single image at one location

You can see a video of this machine printing a one-color image in one location here:

This hard hat printing system is capable of printing images up to four inches in diameter. The operator controls all functions through a five-inch display panel which allows for control of such functions as timer delays, delays on front and back, timed inking, counter, and machine cycle speed. The rotary fixture, pretreat station and shuttle transport are also controlled through the touchscreen display panel.

Contact us today to learn more about this great opportunity to own a tested, never-used, turnkey hard hat pad printing system!

Catheter Marking Machine

The global coronavirus pandemic has forced the cancellation of all in-person trade shows for the remainder of 2020. It has also brought business travel to a standstill, resulting in far fewer opportunities to connect with customers and prospects. Throughout it all, Engineered Printing Solutions has remained open and has been actively supporting and serving the medical device manufacturing industry. With the cancellation of BIOMEDDevice Boston, EPS will be hosting a Virtual Trade Show on September 17th and 18th. We would love the opportunity to “see” you and share your current projects with us.

Is now the right time to go digital?

Our Virtual Trade Show is free to attend. The September 17th session will be devoted to pad printing and will include machine demonstrations as well as live Q & A. September 18th will be devoted to industrial inkjet, also featuring live machine demonstrations and Q & A. Bring your questions about adhesion, fixturing, whatever you want. Space is limited, so please reserve your spot today!

Reserve Your Spot Today!

Day 1 will begin with remarks from the EPS leadership team, providing a brief company history and outlining our capabilities. Next, we will cover ink-mixing and cliché preparation for pad print applications. We will then cover setting up a pad print machine for printing, and will demonstrate a catheter pad printer. The remainder of the morning session will be open to Q & A.

Day 2 will focus on industrial inkjet printing. We will start with a general discussion about converting from analog to digital product-marking solutions, and some of the factors to consider in making that investment. We will then demonstrate the BottleJet 2.0, an industrial inkjet printer designed to print drinkware and other cylindrical objects. We will also demonstrate flatbed inkjet printers and finally, singlepass inkjet printers. As on the previous day, the remainder of the morning session will be open to group discussion and Q & A.

On both days, our sales engineers will be available in the afternoon for one-on-one breakout sessions. Bring your product-marking challenge to us, and let’s get down into the weeds of your project! Don’t miss this free opportunity to plumb our twenty-five years’ worth of experience in building product-marking machines for every application.

Studies indicate that 90 percent of snap judgments made about products are based on color alone.

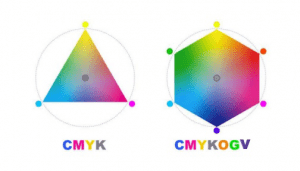

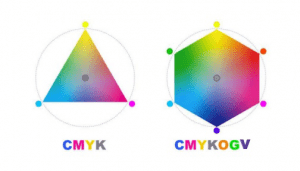

One of the most exciting recent developments at Engineered Printing Solutions has been the expansion of process colors to singlepass machines. Often called extended gamut machines, the addition of orange, green, and violet allows for the printing of many more colors than CMYK alone, without the use of spot colors.

Why Extended Gamut?

The demand for extended color gamuts largely parallels the adoption of digital part-decoration over traditional analog methods. Historically, printers using analog methods such as offset, screen, or pad printing have added spot colors to achieve precisely the results their customers demanded. By contrast, industrial inkjet printers have historically built up color using just cyan, magenta, yellow, and black. This simplifies printer design, but by using just these four colors, many colors in the visible spectrum are unachievable.

The addition of orange, green, and violet greatly extends the color gamut over CMYK alone.

Expanding from CMYK to CMYKOVG is the most common method of extending the gamut. Typically, in CMYK process there have been gaps or smaller defined areas of the deep green, bright orange or violet shades. Adding these colors to the process results in a broader range of colors available to print via inkjet. Dense reds such as the one used in the Coca-Cola™ logo have also presented challenges with traditional CMYK process. The addition of orange, green, and violet make that color more achievable without having to increase resolution or ink builds.

The addition of orange, green, and violet significantly expands the possible gamut, allowing more vivid designs and greater possibilities for economic short runs. The more colors achievable, the more products you can run, and the better you can serve your customers.

As the conversion from analog to digital becomes more widespread, customers are beginning to require higher quality images to convert. Some are requiring colors that are typically difficult with just CMYK. Others are simply looking to duplicate the colors already in place using current offset/analog systems.

What Are the Drawbacks of an Extended Color Gamut?

The print engine itself is the most costly part of most print systems, so additional print heads along with their concomitant costs such as necessary ink management systems will add to the price of a print system. OEM and contract part decorators will have to make their own ROI calculation based on the size of runs, the number of SKUs to run, and the desired image quality. Fortunately, our Sales Engineers have helped many customers with just this sort of calculus, and are eager to help you design your next printing solution.

Want to learn more about extended color gamuts? Drop us a line!

At Engineered Printing Solutions, we design direct-to-object product-marking machines with custom automation and part-handling. As it says on the bottom of every page on this site, “No two print machines are alike.”

This is no mere slogan. So many factors go into the design of a particular printing machine, from part topography and substrate to image size and quality to desired throughput speed.

And this does not even broach the performance requirements of the part. Perhaps it is an engine part that will be exposed to heat, dirt, and solvents. Perhaps the part is drinkware and the image must withstand multiple trips through the dishwasher. Every project has its unique challenges, and for this reason, no two print machines are alike.

This fact has several implications, one of them being that we do not have an inventory of standard machines sitting on the shelf that we sell directly into various industries. Another consequence of designing and building bespoke part-decorating equipment is that over the years we have learned the right questions to ask potential customers in order to create the printing machine that fits their needs perfectly. As a result, our Sales Engineers have gained expertise in Operations Management.

It all starts with a few basic questions. What is the part topography? What is the substrate? hat is the size and desired quality of the image to be printed? And perhaps most importantly, what is the desired throughput in parts per hour? Answers to these questions will help our Sales Engineers to find the right solution for you.

I was reminded of the depth of knowledge among our sales staff—many of whom started with the company as technicians, so they have hands-on knowledge of the machinery they sell—at our weekly sales meeting recently. As is often the case, the Sales Engineers were discussing a particular project that one among them was wrestling with for a potential customer. The Sales Engineer was proposing a digital solution but was struggling both with the curvature of the part and also the desired throughput. Initially, he proposed increasing throughput by adding a second print array, but was discouraged from doing so by his colleagues, as multiple print arrays quickly become prohibitively expensive.

One person pointed out that the limited-palette artwork and part topography suggested that an automated pad printing solution might be more appropriate and cost-effective for the customer. At this point, someone proposed twin independent pads in order to double the throughput. A rotary table was also proposed as a solution to increase throughput, but it was quickly concluded that neither of these solutions addressed the real constraint to higher throughput: the fact that the operator still only has two hands with which to load parts. (If you think about it, a rotary table primarily serves the purpose of permitting parts to move past inline pretreatment, but it does nothing to increase throughput, as the same person must load parts, whether onto a rotary table or directly to the print station.)

The important take-away from this is that every project at EPS starts with basic questions regarding throughput, part topography, and image size and quality. All hardware considerations flow from this information. Truly, no two print machines are alike.

Want to find out more about bespoke product-marking solutions for your project? Drop us a line!

As the novel coronavirus has swept the globe, Engineered Printing Solutions has chronicled the response of the manufacturing sector to the sudden halt of production for many products as well as the rapid shift to production of products used in the fight against the pandemic. We have also reported about our own response to the challenges of keeping our employees safe and healthy even as we and our customers are deemed essential in the struggle to control the spread of the disease.

As we have reported, we have stayed open and healthy through strict adherence to CDC and Vermont state guidelines, which has meant that we have met and responded to heightened interest in catheter-marking machines.

KP08 Catheter Printer

EPS has a long history of serving the catheter industry. Almost since our inception as Pad Print Machinery of Vermont, we have been building machines to mark catheters. Over that time, we have designed and built pad print machines for marking catheters with a range of part-handling capabilities. We tell our customers that no two machines are alike, and a look at the array of upstream and downstream solutions we have devised shows just how true that is. From vacuum-fed part-loaders to downstream cutters and bobbins, we have built catheter-marking machines that can either spool the finished part or cut it to length. From single-color catheter pad printers to pad print machines that print as many as 14 colors, as well as several inline pretreatment options, our catheter-marking machinery is designed to integrate with your production line at the throughput speeds you require. And with an Ink Department that can mix custom Class VI Medical Grade Inks, you are sure to get just the colors you need.

Vacuum-fed catheter part feeder

Want to find out more about how we have served the medical device industry for years, particularly the catheter industry? Take a look at our Medical Device Part-Marking Machines page. There you will see a variety of videos catheter-marking machines we have built over the years. If you watch a few of the videos, you will notice that, while each machine may resemble the others when it comes to the actual pad printing on the part, the upstream and downstream capabilities of each machine are unique to the customer. Truly, “No two print machines are alike.”

If you’ve got a project involving catheter-marking, drop us a line. Let us design a solution for you!

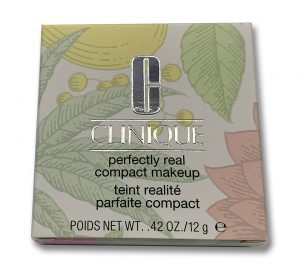

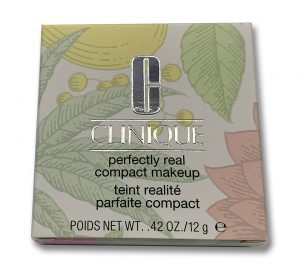

The metallic effect on this cosmetics packaging was created with cold foil printing.

Hot foil stamping has been around for centuries. With this method, a die uses both heat and pressure to adhere the foil and a heat-activated adhesive to the substrate.

Cold foil printing is a relatively new technology. Inkjet print heads jet UV-activated adhesive onto a substrate, and foil is briefly pressed onto the substrate and passed under a UV light. The adhesive cures instantly, and the foil is stripped away, remaining only where there was adhesive.

At EPS we are excited about the decorative possibilities of cold foil printing. To us, the usual advantages of digital inkjet (the potential for variable data, or print-runs of just one unit) only add to the advantages of cold foil printing versus hot stamping. In addition, heat and pressure are not viable options for some substrates. Furthermore, drop-on-demand technology means gradients are possible.

Advantages of Cold Foil Printing vs. Hot Stamping:

- Heat, pressure not viable options for some substrates

- Drop-on-Demand means gradients are possible

- Lower tooling costs

- Less make-ready and downtime

- Inline process vs. secondary process

- Colors, varnishes, coatings can be applied inline over foil

- Reduced need to store semi-finished goods;

- Faster speed-to-market

But the biggest single advantage of cold foil printing over hot stamping is the lack of tooling costs. With hot stamping, whether you are making one part or a million, you first need to make a stamping die. With cold foil printing, there is no need for a die, and thanks to variable data capabilities, a part decorator could have a production run of a million parts, each one marked differently.

Because there is no die to change, make-ready and downtime is much less with cold foil. According to some estimates, hot stamp average changeover time can take anywhere from a half-hour to 8 hours, whereas changeovers on a digital inkjet print machine can be as simple as a few clicks of a mouse.

Other advantages of cold foil printing revolve around the fact that cold foil is an inline process as opposed to a secondary, offline process, meaning final part decoration can occur immediately after the part pops out of an injection mold. Not only does this eliminate the need to store and handle semi-finished goods, but colors, varnishes, and other coatings can be applied inline over the foil in a seamless, integrated process. All of these factors lower cost and increase speed-to-market.

You can read about how one company converted to cold-foil printing here.

Want to find out more about cold foil printing? Drop us a line!

After a terrible year in which so far over 260,000 Americans have succumbed to the novel coronavirus, and with millions more deaths worldwide, it appears as though there is light at the end of the tunnel. No fewer than three different vaccines are either in final stages of testing or are in the initial phases of being rolled out to patients.

After a terrible year in which so far over 260,000 Americans have succumbed to the novel coronavirus, and with millions more deaths worldwide, it appears as though there is light at the end of the tunnel. No fewer than three different vaccines are either in final stages of testing or are in the initial phases of being rolled out to patients.

Engineered Printing Solutions is pleased to announce a new version of its celebrated

Engineered Printing Solutions is pleased to announce a new version of its celebrated

Enhance the safety of your employees while promoting brand awareness. Putting your logo on your company’s hard hats isn’t just good marketing; it could also

Enhance the safety of your employees while promoting brand awareness. Putting your logo on your company’s hard hats isn’t just good marketing; it could also